SVS Hydraulics Pvt.Ltd. is a professionally managed organization established in 2000. SVS Hydraulics Pvt.Ltd. located in Hyderabad, Telangana, India with 13000 sft covered area and 6000 sft open area self-equipped with designing, fabrication, machining, assembling and testing facilities. As a technology savvy organization, SVS Hydraulics Pvt.Ltd. is engaged in R&D activities on a regular basis to understand the customer needs and to meet the international standards. All the products are reliable, efficient, cost effective and user friendly.

SVS Hydraulics Pvt.Ltd. manufactures wide range of products like Hydraulic Power pack, Hydraulic cylinders, Hydraulic presses, Material handling equipment like Scissors lift, Dock levelers, Hydraulic lifts/Stackers and Customized material handling equipment’s, Bailing presses, Mobile hoardings and Customized special purpose equipment’s, Stretch forming machine, passengers lifts etc.

SVS Hydraulics Pvt.Ltd. is specialized in developing composite process machinery like pultrusion plants, pultrusion dies, mat slitters, GRP pipe end grinding (Calibration) machines, GRP pipe extractors, Hydro testers, Beam strength test machine, Hydraulic presses, Filament winding machine, Pultrusion rebar/rock bolt machine(Pull winding), continuous sheet making machine, SMC machine, DMC mixers etc. are also offered from the product range.

SVS Hydraulics Pvt.Ltd. continuous efforts for development of composite process machinery to suit customer requirements at affordable pricing keeps SVS Hydraulics Pvt.Ltd. ahead in domestic and international market.

The company’s commitment to quality is exemplified by its inclination towards it and is certified by QMS as an ISO 9001-2015 company.

Its dedicated R&D team enables it to constantly be in an evolution stage to bring out more and more innovative products. Right from designing stage to post installation stage, stringent supervision check is carried out at all stages to ensure the final quality.

SVS Hydraulics Pvt.Ltd. works with quality objective of pursuing 100% customer satisfaction and the quality guideline being customer supremacy, business ethics and constant improvement.

SVSHPL strives to help and develop processes and designs to keep the composite industry moving forward. SVSHPL feels that by training and delivering the best machinery on the market, we can help grow the composite industry worldwide. If we cannot help with our years of knowledge in this industry, we can certainly send a customer in the right direction. We do not try to sell machinery or services to every customer. We try to help evaluate production requirements and investment payoffs.

WE CAN’T SPELL SUCCESS WITHOUT YOU

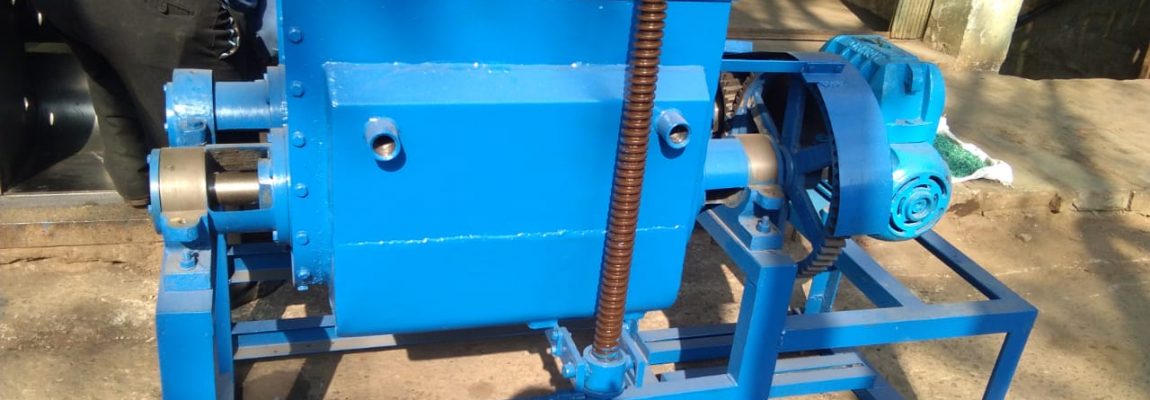

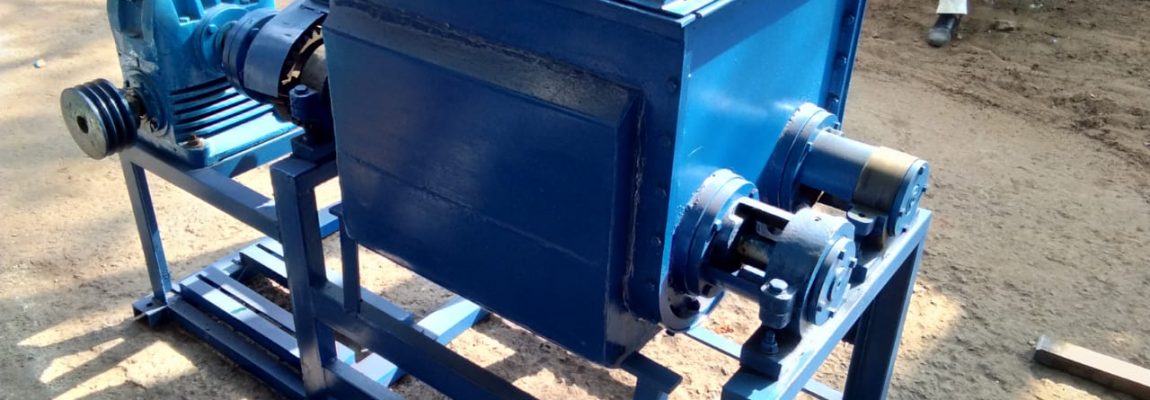

ABF introduces the modern and heavy duty, strong built Sigma mixer (kneader) to produce uniform mixing and kneading heavier viscosity materials. The Sigma mixture is suitable for many applications like mixing, kneading, Grinding, dispersion, drying etc. The sigma mixer have application to produce highly viscous materials like different kinds of Chemical, Dyes & Pigments, Paint, Polymers Plastic, Putties, Plastic, Pharmaceuticals, Printing ink, stiff pastes, adhesives, polyester Compounds, flush colors, brake lining compounds, resign, soap, PVC coatings, Rubber compounds, Confectionery, Magnetic Tape Coatings, Ceramic, Carbon Black, doughs,, Food Products, Fiber Glass, Grease, Lead Storage Battery, Soap & Detergent etc.

Sigma mixer, the tangential action of mixing and kneading is thoroughly obtained by ‘Z’ (SIGMA) shaped kneading blades, which rotates very accurately at different speed towards each other causing product to be transferred from blade to blade. Discharge of the mixed product is achieved by tilting the container or through the valves at the bottom or by means of an extrusion screw below the container if provided

WhatsApp us