SVSHPL manufactures Pultrusion machines and every other equipment used in Pultrusion operations. SVSHPL produces as well panel production lines. SVSHPL’s focus is to assist companies in the industry to achieve maximum production and/or low cost production for their fiberglass and composite products. We feel that Pultrusion is the cheapest manufacturing process for fiberglass and composites. SVSHPL Pultrusion machines come from our experience in the production of parts before we ever built any machinery. We strive to understand the process before we ever undertake equipment manufacturing.

SVSHPL’s principles have been building composite manufacturing machinery for over 15 years. Our expertise in the composite industry ranges from Pultrusion machines to panel production lines. We have built machinery for some of the largest companies in the world, including but not limited to: PULTRUSION PLANTS ( Machines, Dies, Mat Slitters, Rebar), GRP Pipe Plants ( Filament winding machines, Extractors, Calibration, Hydro tester), hydraulic Presses, (Up to 1000 Metric Tons, Custom built), Hydraulic power Packs, Hydraulic Cylinders, Bailing Presses, Material Handling Equipments ( Scissor lifts, Stackers, Car lifts, Mobile Hoardings, FRP Insulator Plant ( Pultrusion Machines, Crimping machines, Tensile strength testing machines ( Horizental,Vertical), custom built and many more. SVSHPL engineers have set industry standards and milestones for years, some of which are still unequalled today. If you want to be in the forefront of the industry, give us a chance to help you get there.

SVSHPL’s principles have been building composite manufacturing machinery for over 15 years. Our expertise in the composite industry ranges from Pultrusion machines to panel production lines. We have built machinery for some of the largest companies in the world, including but not limited to: PULTRUSION PLANTS ( Machines, Dies, Mat Slitters, Rebar), GRP Pipe Plants ( Filament winding machines, Extractors, Calibration, Hydro tester), hydraulic Presses, (Up to 1000 Metric Tons, Custom built), Hydraulic power Packs, Hydraulic Cylinders, Bailing Presses, Material Handling Equipments ( Scissor lifts, Stackers, Car lifts, Mobile Hoardings, FRP Insulator Plant ( Pultrusion Machines, Crimping machines, Tensile strength testing machines ( Horizental,Vertical), custom built and many more. SVSHPL engineers have set industry standards and milestones for years, some of which are still unequalled today. If you want to be in the forefront of the industry, give us a chance to help you get there.

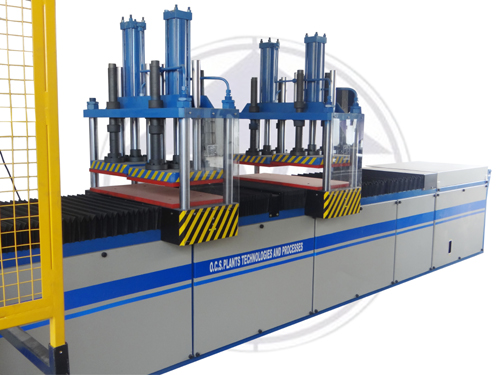

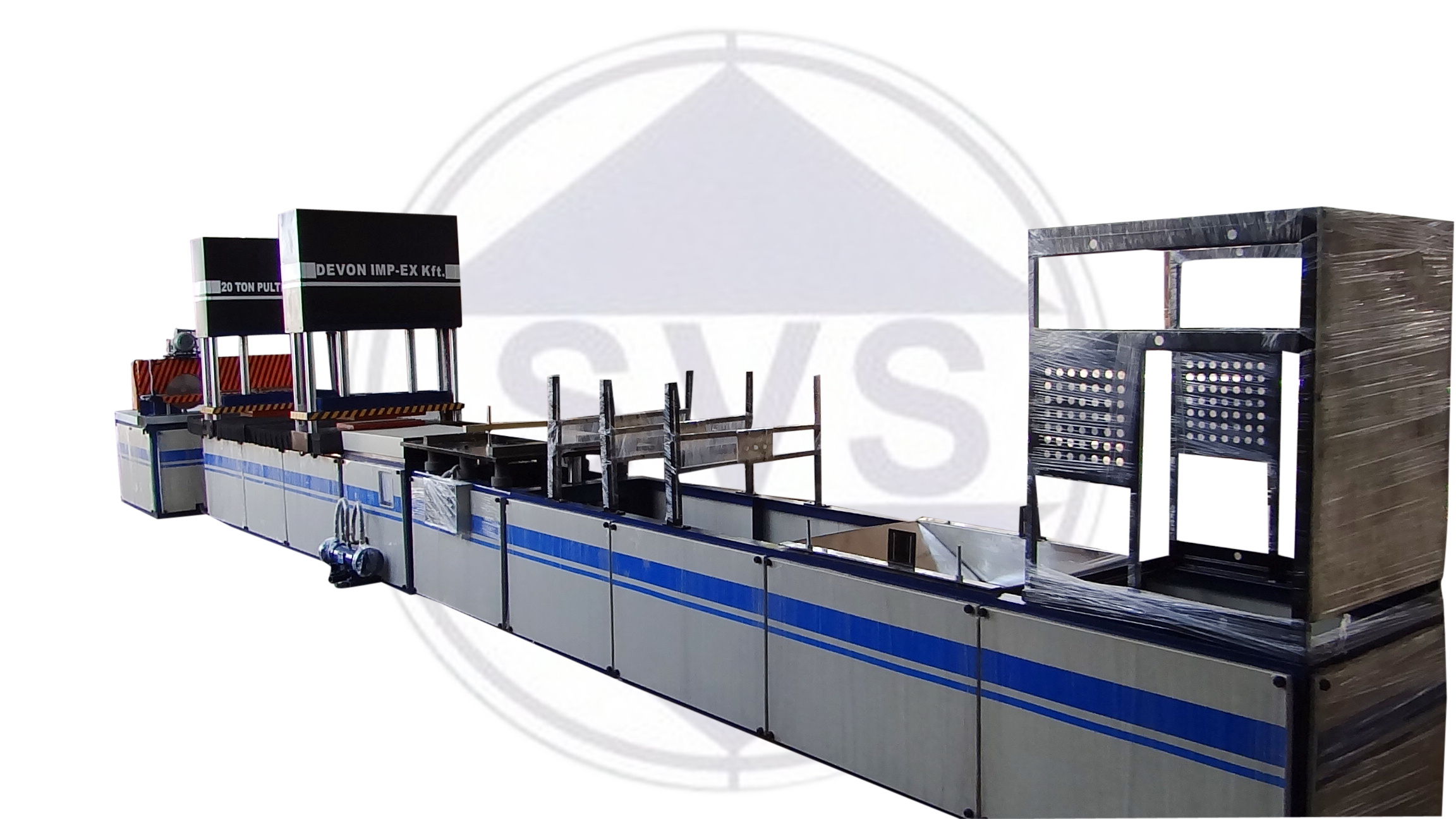

SVSHPL designs, engineers, tools and manufactures machinery for Complete range Polymer Insulator Machinery. The SVSHPL machines are designed to meet the most demanding manufacturing requirements. Extremely fine detail of small delicate parts and complex profiles of large structural components can be produced to exacting precision. Profile envelope size and pull and clamp capacities are available to fill any requirement.

SVSHPL Pultrusion machines use state-of-the-art programmable controllers, power units, pumps, valves and manufacturing technology. Every care has been taken to maximize equipment operating efficiency and minimize downtime.

SVSHPL machine frames are constructed of heavy-duty steel to provide a stable processing platform, which is essential for quality production. A strong frame enables processing very dense composites which have a high fiber-to-resin composition. The higher the fiber content of the pultruded part, the stronger the part and the higher its performance.

SVSHPL provides the most comprehensive design, equipment, processing and technical support services available in the composites industry.

When considering new process equipment or upgrading existing equipment, call SVSHPL and let us help you increase you manufacturing capacities and improve your competitive edge in the marketplace.

SVSHPL strives to help and develop processes and designs to keep the composite industry moving forward. SVSHPL feels that by training and delivering the best machinery on the market, we can help grow the composite industry worldwide. If we cannot help with our years of knowledge in this industry, we can certainly send a customer in the right direction. We do not try to sell machinery or services to every customer. We try to help evaluate production requirements and investment payoffs.

WE CAN’T SPELL SUCCESS WITHOUT YOU

SVSHPL designs, engineers, tools and manufactures machinery for Pultrusion process operations. The SVSHPL machines are designed to meet the most demanding manufacturing requirements. Extremely fine detail of small delicate parts and complex profiles of large structural components can be produced to exacting precision. Profile envelope size and pull and clamp capacities are available to fill any requirement.

SVSHPL Pultrusion machines use state-of-the-art programmable controllers, power units, pumps, valves and manufacturing technology. Every care has been taken to maximize equipment operating efficiency and minimize downtime.

SVSHPL machine frames are constructed of heavy-duty steel to provide a stable processing platform, which is essential for quality production. A strong frame enables processing very dense composites which have a high fiber-to-resin composition. The higher the fiber content of the pultruded part, the stronger the part and the higher its performance.

SVSHPL provides the most comprehensive design, equipment, processing and technical support services available in the composites industry.

When considering new process equipment or upgrading existing equipment, call SVSHPL and let us help you increase you manufacturing capacities and improve your competitive edge in the marketplace.

SVSHPL notching machines are typically used in grating production. SVSHPL offers custom equipment for offline production of your composite Pultrusion. We have built MAT SLITTER, RESIN FEEDING UNIT, NOTCH CUTTING MACHINE, PUNCHING MACHINE and machining equipment for grating.

Tell us your needs for offline fabrication and we will either help you with the equipment or direct you to the sources to produce the machinery you need.

1. MAT SLITTER

2. RESIN FEEDING UNIT

3. NOTCH CUTTING MACHINE

4. PUNCHING MACHINE

5. CHOP SAW MACHINES / MANUAL CUTTERS ( OFF LINE)

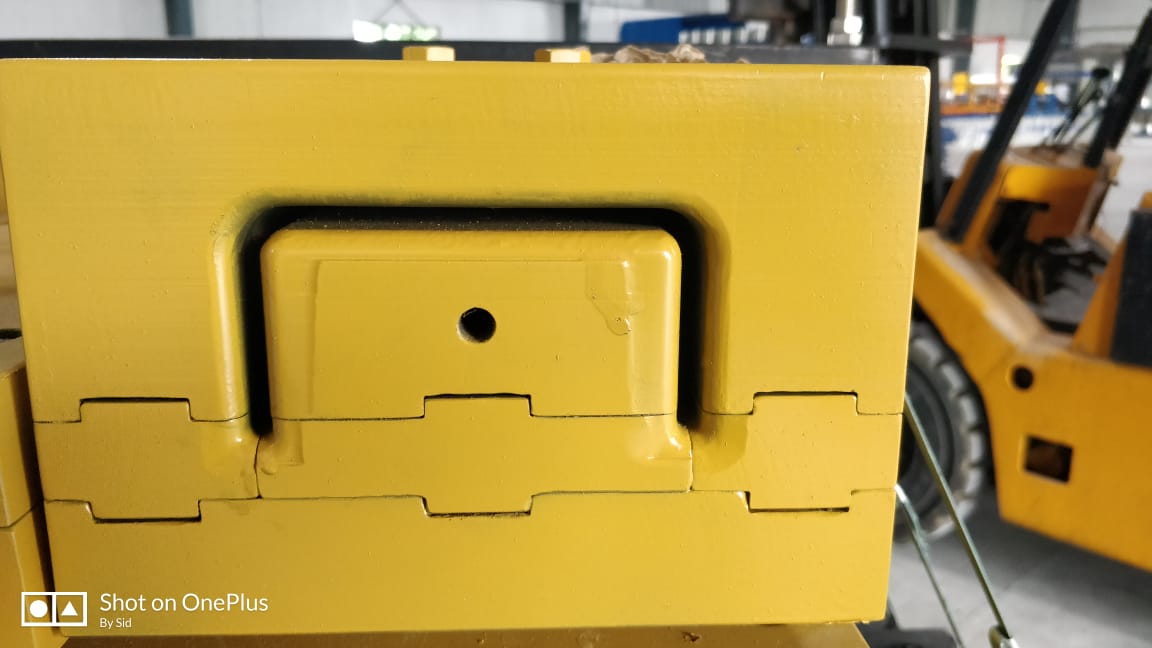

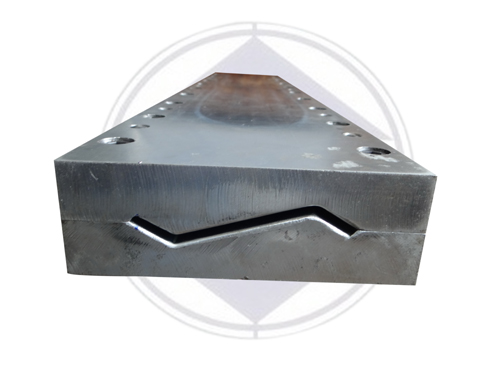

SVS HPL have built over 800 dies in operation worldwide. Pultrusion Tooling Inc. is dedicated to the design and the fabrication of Pultrusion dies, performers and grippers. Injection die technology has been developed at SVSHPL for many years now and is today one of the key solution for clean composite process.

Let us quote on your complete Pultrusion system (including Preforming section & grippers) with our machines and die technology.

We use the best materials and deliver tooling that will last under rugged production abuse. Thermal heat transfer and proper wetting is the key to success in any production composite application.

Our years of experience in tooling and production will certainly deliver the best product for you.

WhatsApp us